Automobile Pressure Test

Introduction

With unmatched resolution and accuracy, the WPS500X automotive pressure sensor can be used to quickly analyze pressure in many automotive systems.

- Accurate measurements to 500psi

- Ultra-fast 100µs response time

- Amplification function to enhance analytical capabilities

- Internal rechargeable lithium battery

- Built-in pressure relief/bleed valve

- Auto Zero

- High noise suppression

- Temperature compensation

The WPS500X has an ultra-fast 100µs response time from full scale 0% to 90% and is sensitive to approximately 0.07psi (5 mbar).

This gives you a precise display of rapidly changing signals and can be used across a wide range of pressures.

Hydraulic Pressure Measurement Test

WPS600 Hydraulic Pressure Sensor

With its high accuracy and large range, the WPS600 hydraulic pressure sensor is used in conjunction with a Pico oscilloscope for quick analysis of pressurized systems.

- Accurate measurements up to 600 bar (8700 psi)

- Ultra-fast 100 microsecond response time (from full scale 0% to 90%)

- Built-in rechargeable LiPo batteries

- Auto Zero

- High noise shielding

- Temperature compensation

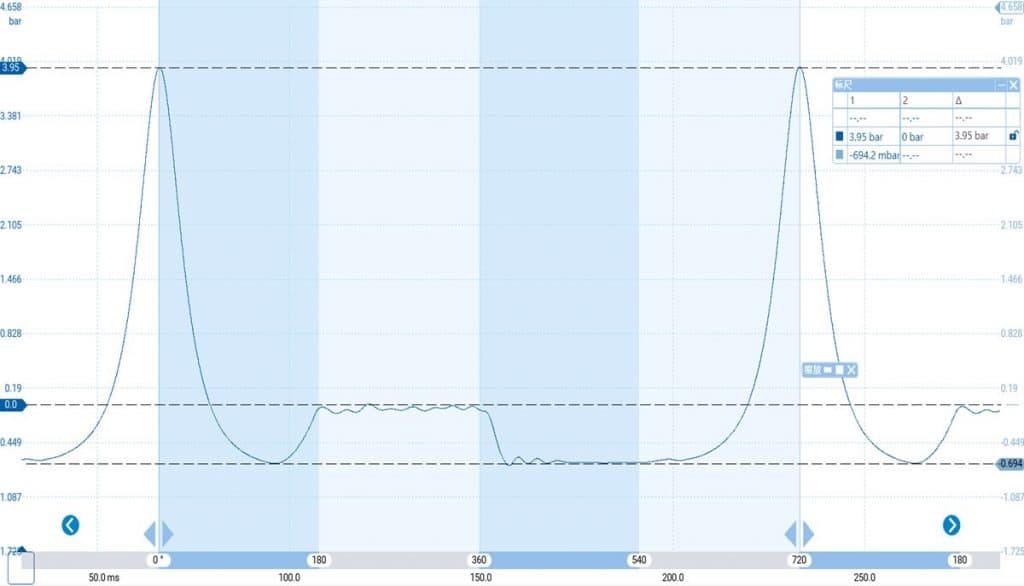

The Pico Engine and Hydraulic Kit combines our diesel diagnostic kit with two WPS600C hydraulic sensors, allowing you to accurately and quickly diagnose faults on many different types of mobile machinery. PicoScope has been selected by dozens of automotive and equipment manufacturers for its unique combination of value, reliability, performance and guidance.

By combining a high-precision hydraulic sensor with the PicoScope kit, you can now see hydraulic pressure in the same timeframe as the engine control signals, giving you a complete picture of how the system is operating. You can now see the exact torque at which the valve begins to move in the hydraulic system and compare it directly to the associated electronic controls.

Exhaust Pressure Test

Introduction

The FirstLook Engine Diagnostic Sensor ( TA014 ) provides a fast and accurate way to diagnose automotive engine problems such as burnt valves, bad injectors and other performance issues without disassembling the engine.

When a FirstLook Engine Diagnostic Sensor is connected to the engine exhaust or vacuum line, a complete picture of the engine's core performance is displayed on the oscilloscope.

Working Principle

Working Principle

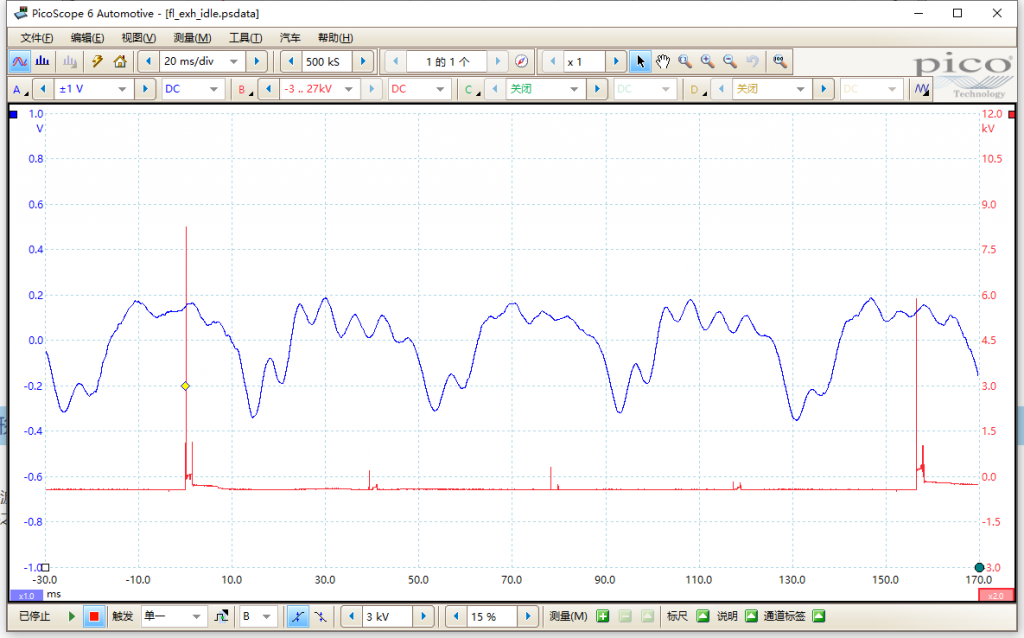

FirstLook sensors detect the pulses generated by the normal operation of an internal combustion engine. All engines produce defined pulses, so any change or abnormality in the pulses can be traced to an engine problem. These pulses are also affected by unburned fuel in the exhaust, an abnormality that can also be detected and displayed.

Typical applications for the FirstLook sensor may be mounted in an exhaust pipe or in a vacuum port to detect pulsations in the air flow. When connected to your oscilloscope, it displays the operating status of valves, cylinders and injectors in real time. Suitable for any two- or four-stroke gasoline or diesel engine. Locates a particular cylinder by displaying timing triggers. The ability to identify the exact cylinder where valve or injector problems are occurring saves valuable diagnostic time and costs.

Blue: Exhaust Pulse, Red: Ignition Signal

Honghong will provide you with any support you need!

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.