The Challenge of Predictive Maintenance

Predictive maintenance sounds simple, however, it is not easy to implement and ensure that data is collected accurately and consistently and analyzed accurately. It is difficult to find skilled and experienced resources to translate vibration data into predictive maintenance insights.

Proven Predictive Maintenance Programs

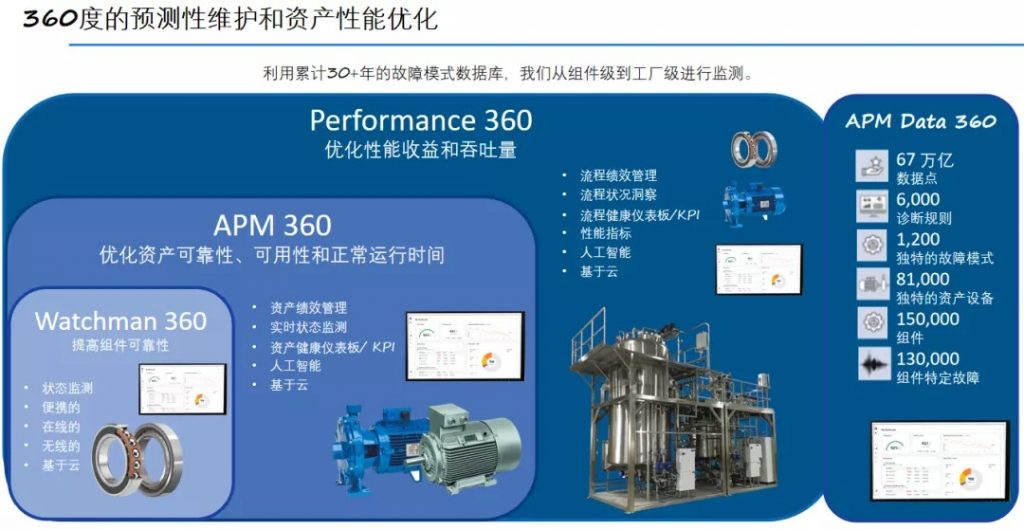

Together with the predictive maintenance experts, HONGKEI offers the WATCHMAN 360 predictive maintenance program, which is based on a database with more than 30 years of experience and an accumulation of test data: more than 6.7 billion data points on equipment such as motors, pumps, fans, compressors, transmissions, gearboxes, etc. The WATCHMAN 360 program is based on a database with more than 30 years of experience and test data accumulation: more than 6.7 billion data points on equipment such as motors, pumps, fans, compressors, transmissions, gearboxes, etc.

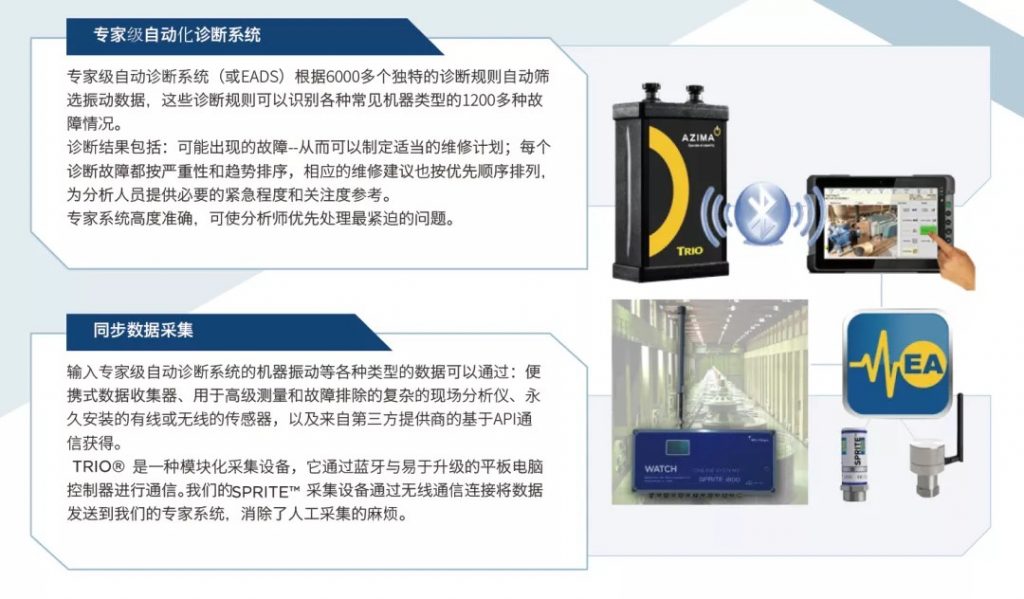

The WATCHMAN 360 provides important machine health information beyond vibration data by quickly filtering vibration measurements and applying more than 6,000 unique rules to identify more than 1,200 fault types across a wide range of machine types.

ValidatedAutomated Machine Condition Evaluation SystemHundreds of vibration measurements can be processed in just a few minutes to provide you:

- Troubleshooting Results

- Failure Severity

- Maintenance prioritization related recommendations.

Predictive Maintenance Realization Principle

The WATCHMAN360 includes a sophisticated rule-base methodology. In addition to simple monitoring of peaks or spectra with alarms, its test-point change function captures data detected at multiple sets of locations on the machine and compares it to benchmark data from a particular type of machine in the database to make highly accurate automated diagnoses.

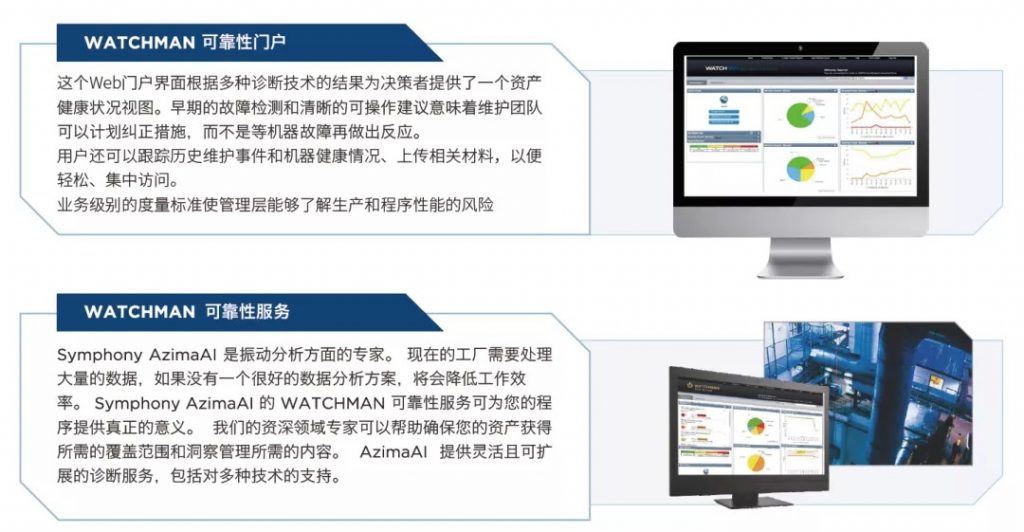

First, we collect data from rotating equipment via wired/wireless vibration sensor devices, handheld data collectors, or online systems; then, the data is uploaded to the Security Cloud, where the diagnostic engine ExpertALERT analyzes the data and the results are shared via the WATCHMAN Reliability PortalTM.

The final information provided includes which machines are malfunctioning, the severity of these malfunctions, and recommended measures to address these malfunctions.

SIAI Predictive Maintenance Program Highlights Organized >>>>Learn More

Contact Us